Product Categories

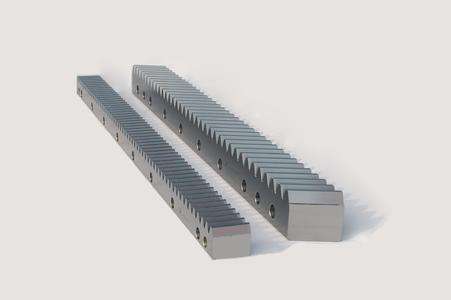

Processing procedure: forging blank → rough machining → tempering → semi-finishing → tempering → finishing.

Machining difficulty: rack modulus is large, the cutting speed of finger milling cutter at the tooth root and the tooth tip is 2.5 times different, to reach the roughness of the tooth surface processing less than R6.3 is relatively difficult, so the process should be innovated.

Distinguish processing: a large number of grinding rack processing, generally by the special production equipment manufacturing, or design manufacturing special indexing mechanism to solve the processing problem, also have design special indexing mechanism in the milling machine processing.But if the number is small, can also be used on the original milling machine accessories, end milling head, division number one stop rack processing and so on, various types.

Professional problem: modulus rack, the difficulty is PI, the common milling machine screw pitch is 6mm, and PI is a decimal, difficult to directly divide.It is easy to operate if it is simplified.

(1) after the fire hanging wheel suspension degree;

(2) change the screw pitch.

In the calculation of dividing hanging wheel, the size of the calculating dividing error depends on the size of PI putting in the proportional value error. In most calculation of PI putting in the proportional value, PI ≈ 3.28571 =(22/7) grinding rack information network is selected, and the error value is 0.0012644.

According to our many years of production experience, about a small number of rack processing, our practice is first milling teeth processing and then fine milling to ensure the rack accuracy 6-8 level, surface finish up to 0.8, follow the "simple, accurate, applicable, bento, reliable" principle.

Previous: TBI ball screw is also known as ball screw and screw

Next: Four heat treatment processes of planetary reducer gear

Related Industry Knowledge

- Comparison of cold rolled and lappe...

- TBI ball screw is also known as bal...

- Four heat treatment processes of pl...

- Precision gearcar burizing and quen...

- Calculation of planetary gear ratio

- The Time Line of Gears

- Ball Screws Used for Latest Innovat...

- Comparison between Rolled and Groun...

- Recirculation System and Attributes...

- Characteristics of spline

- Design and processing technology of...

- Noise on gear box