Product Categories

Linear motion is the one of critical aspects of the new product that is being developed. Great innovation lately in the design for medical devices and laboratory instruments. One of several on-going applications involving wearable pumps driven by ball screws

Integrating all of this function into a single implantable is extremely challenging. Implantable medical devices naturally place extreme requirements on size, materials, lifetime, and reliability. These limitations drive up cost and complexity. Not only that, but servicing the pump requires major surgery!

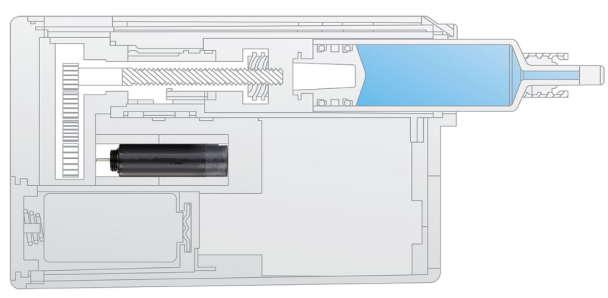

One key is to break down the system into two modules—one implantable and one wearable. The implantable component handles minimal functionality and consists simply of a balloon. The wearable component enjoys much looser design requirements. Wearable pump is used to drive compacted air through a catheter that passes into the body.

A wearable pump offers the benefits of being small, quiet, and very dependable. That is where precision ball screws come into play. It has standard miniature screws in diameters 3 to 16 mm. The diameter typically required for this application ranges from 8 to 12 mm. Convention products can be developed as well for applications that need it. This improves the surface quality of the shaft threads for reduced friction torque, quieter operation, and longer life.

Related Industry Knowledge

- Comparison of cold rolled and lappe...

- TBI ball screw is also known as bal...

- About rack processing

- Four heat treatment processes of pl...

- Precision gearcar burizing and quen...

- Calculation of planetary gear ratio

- The Time Line of Gears

- Comparison between Rolled and Groun...

- Recirculation System and Attributes...

- Characteristics of spline

- Design and processing technology of...

- Noise on gear box

- Characteristics of gear box

- Simple overview of the gear box

- experience on pulleys

- Pulley Assembly considerations

- Pulley installation and removal