Product Description

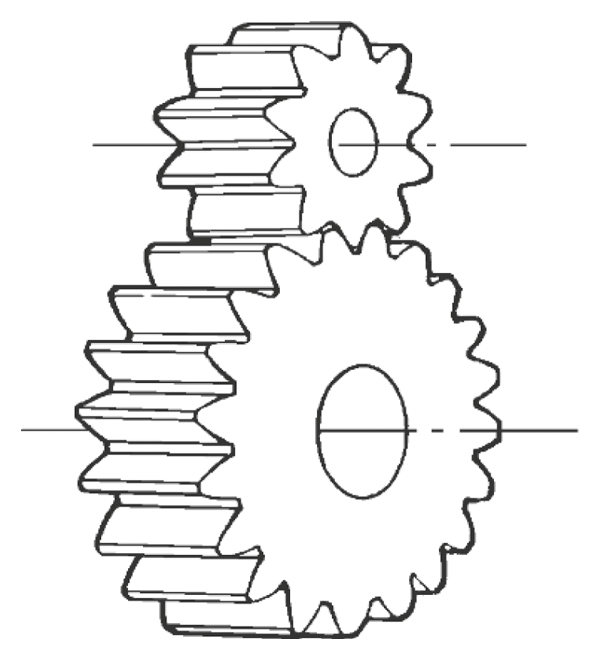

China Manufactory OEM Spur and Helical Gear

Description:

Name: Spur gear

Material: Steel, Aluninum, brass

Features:

1. Competitive price

2. High quality

3. OEM service provided

4. Experienced in machining

5. Custom services provided

Packing & Delivery:

Tight packaging to protect the product from damage. Support a variety of payment and transportation methods.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

| Application: | Industry |

|---|---|

| Hardness: | Hardened |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

What are the environmental considerations when using spur gears?

When using spur gears, there are several environmental considerations to keep in mind. Here’s a detailed explanation:

1. Lubrication:

Proper lubrication is essential for the efficient and reliable operation of spur gears. However, the choice of lubricant can have environmental implications. It is important to select lubricants that are environmentally friendly, such as biodegradable or non-toxic lubricants. These lubricants minimize the risk of contaminating soil, water, or air during gear operation or maintenance.

2. Material Selection:

The choice of gear materials can also have environmental implications. Opting for materials that are recyclable or made from recycled content can reduce the environmental impact associated with gear production and end-of-life disposal. Additionally, selecting materials with low toxicity and minimal environmental harm during their lifecycle is important for sustainable gear manufacturing.

3. Energy Efficiency:

Efficient gear design and operation contribute to energy conservation and decreased environmental impact. By optimizing gear design, tooth profiles, and lubrication, it is possible to minimize power losses and increase overall gear system efficiency. This, in turn, reduces energy consumption and the associated environmental footprint.

4. Noise and Vibration:

Spur gears can generate noise and vibration during operation, which can have environmental implications, especially in noise-sensitive or residential areas. Implementing noise reduction measures such as gear tooth profiling, proper lubrication, and noise dampening techniques can help minimize the environmental impact of gear-induced noise and vibration.

5. Maintenance and End-of-Life Disposal:

Proper maintenance practices play a crucial role in minimizing the environmental impact of spur gears. Regular inspection, cleaning, and lubrication can prolong gear life, reduce the need for replacements, and minimize waste generation. Additionally, when spur gears reach the end of their life cycle, it is important to dispose of them responsibly, considering recycling options and proper waste management practices.

6. Environmental Regulations and Compliance:

When using spur gears, it is crucial to stay informed about relevant environmental regulations and standards. Different regions or industries may have specific requirements regarding lubricants, materials, noise emissions, or waste disposal. Adhering to these regulations ensures compliance and minimizes the environmental impact of gear usage.

7. Life Cycle Assessment (LCA):

Conducting a life cycle assessment of spur gears helps evaluate their overall environmental impact. LCA considers the environmental implications of gear production, use, maintenance, and disposal. It provides insights into potential environmental hotspots, allowing for targeted improvements in gear design, material selection, and operational practices.

By considering these environmental considerations and adopting sustainable practices throughout the life cycle of spur gears, it is possible to minimize their environmental impact and promote more environmentally friendly gear systems.

What are the advantages and disadvantages of using spur gears?

Spur gears offer several advantages and disadvantages when used in mechanical systems. Here’s a detailed explanation of the advantages and disadvantages of using spur gears:

Advantages of Spur Gears:

- Simplicity: Spur gears have a simple and straightforward design, consisting of cylindrical gears with straight teeth. Their simplicity facilitates ease of manufacturing, installation, and maintenance.

- Efficiency: Spur gears are highly efficient in transmitting power from one shaft to another. They have minimal sliding friction between the gear teeth, resulting in high mechanical efficiency.

- Cost-Effectiveness: Due to their simple design and ease of production, spur gears are generally more cost-effective compared to other types of gears. They are widely available and can be manufactured in large quantities at a reasonable cost.

- Compactness: Spur gears have a compact design, making them suitable for applications where space is limited. They can be arranged in parallel or stacked configurations to achieve the desired gear ratios within a confined space.

- High Load Capacity: Spur gears can handle high load capacities and transmit substantial amounts of torque. Their teeth are designed to distribute the load evenly across the gear face, resulting in improved load-bearing capabilities.

- Precision: Spur gears provide precise and predictable motion due to the simplicity of their tooth engagement. This makes them suitable for applications that require accurate positioning and synchronization.

Disadvantages of Spur Gears:

- Noisy Operation: Spur gears can produce noise during operation, especially at high speeds. The engagement of the gear teeth generates impact and vibration, resulting in noise that may require additional measures to mitigate.

- Axial Thrust: Spur gears generate axial thrust forces along the gear shafts due to the parallel arrangement of their teeth. This thrust must be properly managed using thrust bearings or other means to prevent excessive axial loading on the gear shafts.

- Limited Speed Ratio: Spur gears are primarily designed for applications with moderate speed ratios. They are less suitable for high-speed applications due to the limitations imposed by the tooth engagement and potential for increased noise and vibration.

- Unidirectional Operation: Spur gears are typically designed for unidirectional power transmission. Reversing the direction of rotation can cause noise, impact, and increased wear due to the abrupt change in tooth engagement.

- Prone to Wear: The sliding contact between the gear teeth in spur gears can result in wear over time, especially under heavy loads or inadequate lubrication. Regular maintenance and proper lubrication are necessary to minimize wear and extend gear life.

It’s important to consider these advantages and disadvantages when selecting gear types for specific applications. While spur gears are well-suited for many applications, other gear types, such as helical gears or bevel gears, may be more suitable in certain situations depending on the requirements and operating conditions.

Are there different sizes and configurations of spur gears available?

Yes, there are various sizes and configurations of spur gears available to suit different applications and requirements. Here’s a detailed explanation of the different options when it comes to sizes and configurations of spur gears:

Sizes: Spur gears come in a wide range of sizes to accommodate different torque and speed requirements. The size of a spur gear is typically specified by its pitch diameter, which is the diameter of the pitch circle. The pitch diameter determines the gear’s overall size and the spacing between the teeth. Spur gears can range from small gears used in precision instruments to large gears used in heavy machinery and industrial equipment.

Module: Module is a parameter used to specify the size and spacing of the teeth on a spur gear. It represents the ratio of the pitch diameter to the number of teeth. Different module sizes are available to accommodate various gear sizes and applications. Smaller module sizes are used for finer tooth profiles and higher precision, while larger module sizes are used for heavier loads and higher torque applications.

Number of Teeth: The number of teeth on a spur gear can vary depending on the specific application. Gears with a higher number of teeth provide smoother operation and distribute the load more evenly, whereas gears with fewer teeth are typically used for higher speeds and compact designs.

Pressure Angle: The pressure angle is an important parameter that determines the shape and engagement of the teeth. Common pressure angles for spur gears are 20 degrees and 14.5 degrees. The selection of the pressure angle depends on factors such as load capacity, efficiency, and specific design requirements.

Profile Shift: Profile shift is a design feature that allows modification of the tooth profile to optimize the gear’s performance. It involves shifting the tooth profile along the gear’s axis, which can affect factors such as backlash, contact ratio, and load distribution. Profile shift can be positive (when the tooth profile is shifted towards the center of the gear) or negative (when the tooth profile is shifted away from the center).

Hub Configuration: The hub refers to the central part of the gear where it is mounted onto a shaft. Spur gears can have different hub configurations depending on the specific application. Some gears have a simple cylindrical hub, while others may have keyways, set screws, or other features to ensure secure and precise mounting.

Material and Coatings: Spur gears are available in various materials to suit different operating conditions and requirements. Common materials include steel, cast iron, brass, and plastic. Additionally, gears can be coated or treated with surface treatments such as heat treatment or coatings to enhance their wear resistance, durability, and performance.

Mounting Orientation: Spur gears can be mounted in different orientations depending on the application and space constraints. They can be mounted parallel to each other on parallel shafts, or they can be mounted at right angles using additional components such as bevel gears or shafts with appropriate bearings.

In summary, there is a wide range of sizes and configurations available for spur gears, including different pitch diameters, module sizes, number of teeth, pressure angles, profile shifts, hub configurations, materials, coatings, and mounting orientations. The selection of the appropriate size and configuration depends on factors such as torque requirements, speed, load capacity, space constraints, and specific application needs.

editor by CX 2023-11-08