Product Description

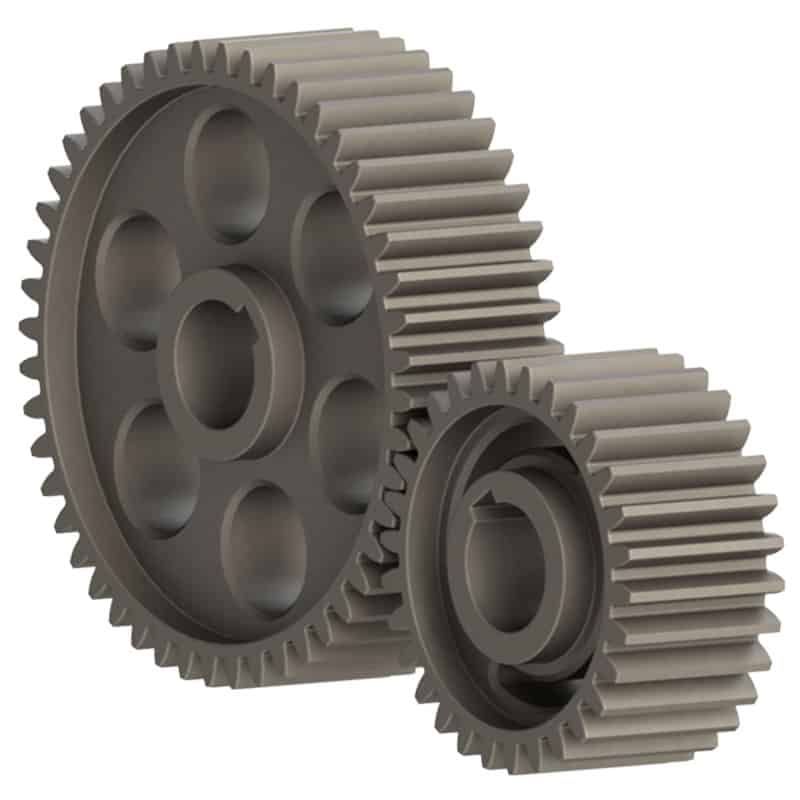

High Quality Steel Material Hardening Teeth Spur Gear

Use:

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric power, telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3. Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket excavator bucket, wheel excavators .

5. Crane:Tower crane, gantry crande, bridge crane.

6. Others:Various elevators, coal plough, ball mill, crusher, recreation machine.

7. Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling:including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling, Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack

8. Other customized Machining Parts according to drawings (OEM).

More Advantages:

1. More competitive prices,

2. Shorter delivery date: 35 days.

3. We are the professional manufacturer in the field of Power Trans. Parts,specially for Timing Pulleys.

4. Produce standard and non-standard

5. Strict QC Management:ISO9001:2008,our engineer,Mr.Wang has specialized in the prodcution for over 20 years.

Packaging & Shipping:

All the products can be packed in cartons,or,you can choose the pallet packing.

MADE IN CHINA can be pressed on wooden cases.Land,air,sea transportation are available.UPS,DHL,TNT,

FedEx and EMS are all supported.

Company:

ZheJiang MIGHTY MACHINERY Co.Ltd., a subsidiary company of ZheJiang Machinery Imp.&Exp. Corp(SCMIEC),which is a wholly stated-owned enterprise established in1980,specialized in producing precision mechanical power transmission products. After years of hard work,Mighty become the holding company of 3 manufacturing factories and also the 1 of the largest enterprise supply power transmission parts in western China.

Mighty’s products are mainly exported to Europe,America and Middle East market. With the top-ranking management,professional technical support and abundant export experience,Mighty has established lasting and stable business partnership with many world famous companies and has got good reputation from world wide customers in international sales.

Factory View:

Exhibition:

FAQ:

1. MOQ

A: Generally, 1 pc for standard parts; contact for nonstandard parts.

2. Delivery Time

A: In stock: within 5 working days. Out of stock: depends on your order quantity.

3. How To Select

A: part number or drawing, catalogue. If no, you can send us your sample, so we can make the drawing and sample accordingly.

4: What is the Warranty for your products?

A:Normally our warranty is 1 year.

Contacts:

| Application: | Motor, Machinery, Agricultural Machinery, and So on |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Manufacturing Method: | Sintered Gear |

| Toothed Portion Shape: | Spur/Helical/Bevel |

| Material: | Steel/Plastic/42CrMo |

| Type: | Spur Gear |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spur gears be used in automotive applications?

Yes, spur gears can be used in automotive applications. Here’s a detailed explanation:

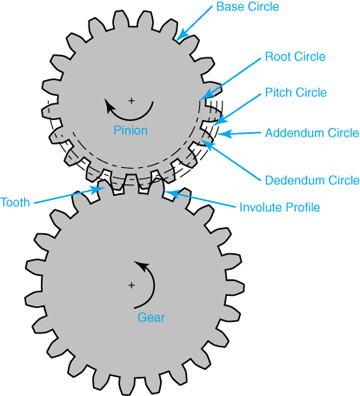

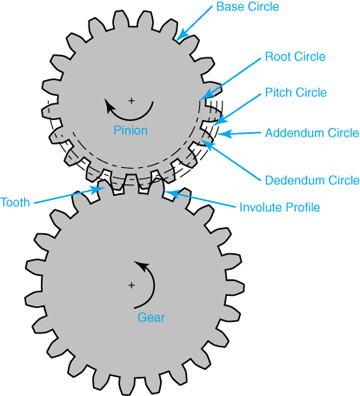

Spur gears are one of the simplest and most commonly used types of gears. They consist of cylindrical teeth that are parallel to the gear axis and mesh with each other to transmit power and motion. While other gear types like helical gears or bevel gears are often preferred in certain automotive applications, spur gears still find their place in various automotive systems and components.

1. Transmissions:

Spur gears are commonly found in manual transmissions, especially in lower gears. They are used to achieve a direct and efficient power transfer between the engine and the wheels. Spur gears in transmissions are designed to handle high torque loads and provide reliable performance.

2. Differential:

In automotive differentials, which distribute power between the wheels while allowing them to rotate at different speeds, spur gears are often employed. They are used in the differential gear train to transfer torque from the driveshaft to the wheels. The simplicity and robustness of spur gears make them suitable for this application.

3. Starter Motors:

Spur gears are commonly used in starter motors to crank the engine when starting a vehicle. They provide high torque and efficient power transmission to rotate the engine’s crankshaft and initiate the combustion process. Starter motor spur gears are designed to handle the initial load and engage smoothly with the engine’s flywheel.

4. Timing Systems:

In automotive timing systems, where precise synchronization of engine components is crucial, spur gears can be used. They are employed in timing belts or chains to drive the camshafts, ensuring proper valve timing and engine performance. Spur gears in timing systems contribute to accurate and reliable engine operation.

5. Accessories and Auxiliary Components:

Spur gears are also utilized in various automotive accessories and auxiliary components. They can be found in power window mechanisms, windshield wipers, power steering systems, and other mechanisms that require controlled and synchronized motion. Spur gears provide cost-effective and efficient power transmission for these applications.

It’s important to note that while spur gears have their advantages, they also have certain limitations. They can generate more noise and vibration compared to gears with helical or bevel tooth profiles. Additionally, spur gears are not as suitable for high-speed or high-torque applications as other gear types.

Overall, spur gears have a significant presence in automotive applications, particularly in manual transmissions, differentials, starter motors, timing systems, and various auxiliary components. Their simplicity, reliability, and cost-effectiveness make them a viable choice for specific automotive gear applications.

How do you install a spur gear system?

Installing a spur gear system involves several steps to ensure proper alignment, engagement, and operation. Here’s a detailed explanation of how to install a spur gear system:

- Preparation: Before installation, gather all the necessary components, including the spur gears, shafts, bearings, and any additional mounting hardware. Ensure that the gear system components are clean and free from debris or damage.

- Shaft Alignment: Proper shaft alignment is crucial for the smooth operation of a spur gear system. Ensure that the shafts on which the gears will be mounted are aligned accurately and parallel to each other. This can be achieved using alignment tools such as dial indicators or laser alignment systems. Adjust the shaft positions as needed to achieve the desired alignment.

- Positioning the Gears: Place the spur gears on the respective shafts in the desired configuration. Ensure that the gears are positioned securely and centered on the shafts. For shafts with keyways, align the gears with the key and ensure a proper fit. Use any necessary mounting hardware, such as set screws or retaining rings, to secure the gears in place.

- Checking Gear Engagement: Verify that the teeth of the gears mesh properly with each other. The gear teeth should align accurately and smoothly without any excessive gaps or interference. Rotate the gears by hand to ensure smooth and consistent meshing throughout their rotation. If any misalignment or interference is observed, adjust the gear positions or shaft alignment accordingly.

- Bearing Installation: If the spur gear system requires bearings to support the shafts, install the bearings onto the shafts. Ensure that the bearings are the correct size and type for the application. Press or slide the bearings onto the shafts until they are seated securely against any shoulder or bearing housing. Use appropriate methods and tools to prevent damage to the bearings during installation.

- Lubrication: Apply a suitable lubricant to the gear teeth and bearings to ensure smooth operation and reduce friction. Refer to the gear manufacturer’s recommendations for the appropriate lubrication type and amount. Proper lubrication helps minimize wear, noise, and heat generation in the gear system.

- Final Inspection: Once the gears, shafts, and bearings are installed, perform a final inspection of the entire spur gear system. Check for any unusual noises, misalignment, or binding during manual rotation. Verify that the gears are securely mounted, shafts are properly aligned, and all fasteners are tightened to the specified torque values.

It’s important to follow the specific installation instructions provided by the gear manufacturer to ensure proper installation and operation. Additionally, consult any applicable industry standards and guidelines for gear system installation.

By carefully following these installation steps, you can ensure a well-aligned and properly functioning spur gear system in your machinery or equipment.

How do spur gears contribute to power transmission?

Spur gears play a crucial role in power transmission due to their specific design and tooth engagement. Here’s a detailed explanation of how spur gears contribute to power transmission:

- Direct Tooth Engagement: Spur gears have straight teeth that mesh directly with each other. This direct tooth engagement ensures efficient transfer of power from one gear to another. As the driving gear rotates, its teeth come into contact with the teeth of the driven gear, enabling the transfer of rotational motion and torque.

- Uniform Load Distribution: The teeth of spur gears distribute the transmitted load evenly across the gear surfaces. The straight, parallel teeth provide a larger contact area compared to other gear types, resulting in improved load-carrying capacity and reduced stress concentration. This uniform load distribution helps prevent premature wear and failure of the gears, ensuring reliable power transmission.

- Efficiency: Spur gears are known for their high efficiency in power transmission. The direct tooth engagement and parallel shaft arrangement minimize energy losses during rotation. The teeth mesh smoothly, resulting in minimal friction and reduced power dissipation. This efficiency is beneficial in applications where maximizing power transfer and minimizing energy waste are crucial.

- Speed and Torque Conversion: Spur gears allow for speed and torque conversion between the driving and driven shafts. By using gears with different numbers of teeth, the rotational speed and torque can be adjusted to match the requirements of the application. For example, a small gear driving a larger gear will result in a higher torque output at a lower speed, while a larger gear driving a smaller gear will result in a higher speed output at a lower torque.

- Directional Control: The arrangement of spur gears can be used to control the rotational direction of the driven shaft relative to the driving shaft. By meshing gears with opposite orientations (e.g., one gear with clockwise teeth and another gear with counterclockwise teeth), the direction of rotation can be reversed. This directional control is essential in applications where the desired motion needs to be reversed or changed.

- Multiple Gear Configurations: Spur gears can be combined in various configurations to form gear trains, allowing for complex power transmission systems. Gear trains consist of multiple gears meshing together, with each gear contributing to the overall power transmission. Gear trains can alter speed, torque, and direction, providing flexibility in adapting power transmission to specific requirements.

- Compatibility with Other Components: Spur gears are compatible with a wide range of other mechanical components, such as shafts, bearings, and housings. This compatibility allows for easy integration into different systems and machinery. Spur gears can be mounted on shafts using keyways, set screws, or other mounting methods, ensuring secure and reliable power transmission.

Overall, spur gears are essential in power transmission systems due to their direct tooth engagement, uniform load distribution, high efficiency, speed and torque conversion capabilities, directional control, compatibility with other components, and the ability to form complex gear trains. These characteristics make spur gears a versatile and widely used choice for transmitting power in various applications across industries.

editor by CX 2023-12-01